Departments

Preparation of the material and paste

|

Piece Formation

|

Thermal Treatment

|

Painting

|

Logistics

The manufacturing process of each ceramic piece is meticulously organized, involving six specialized departments that ensure maximum efficiency and compliance with first-rate standards of excellence.

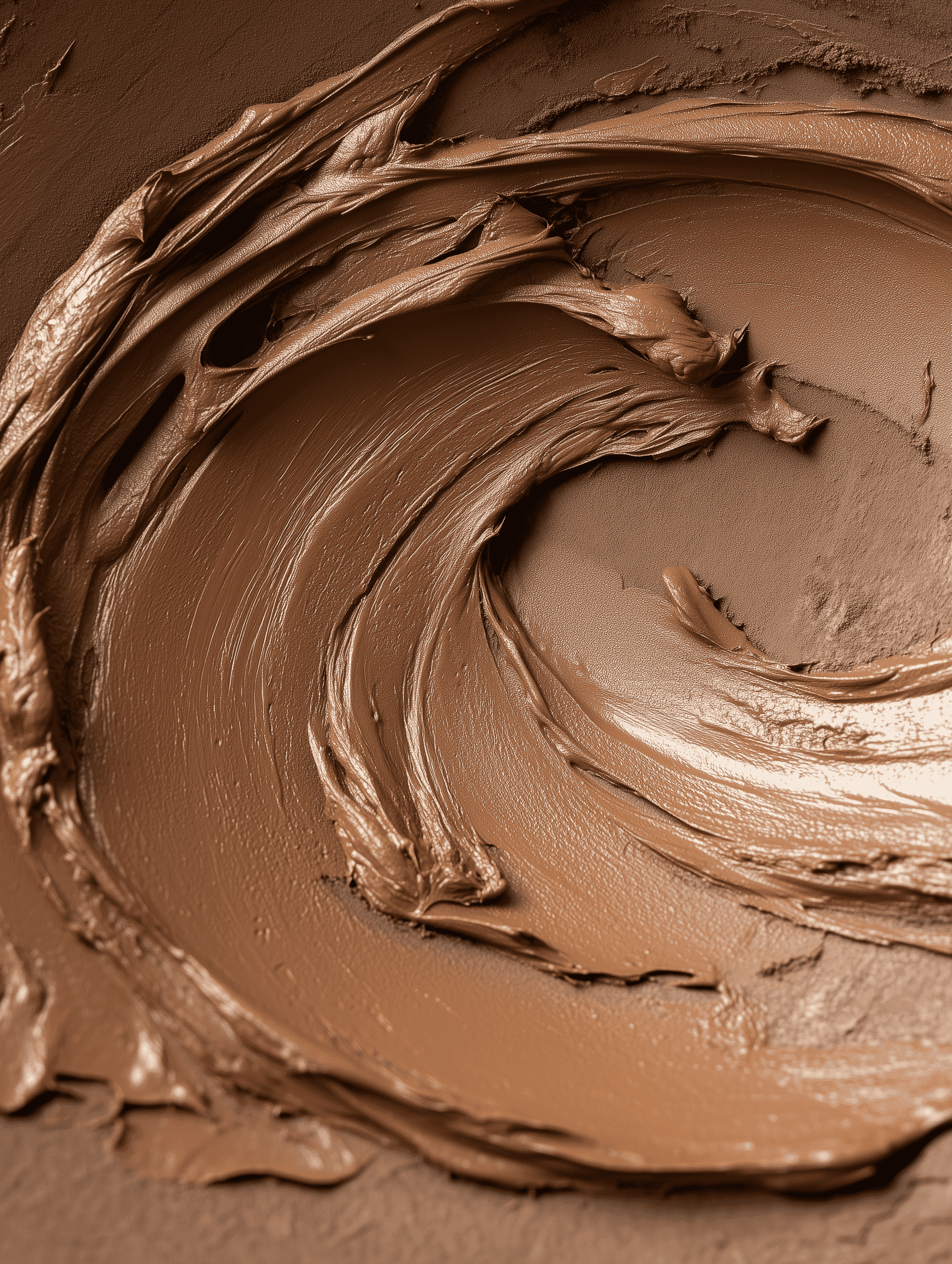

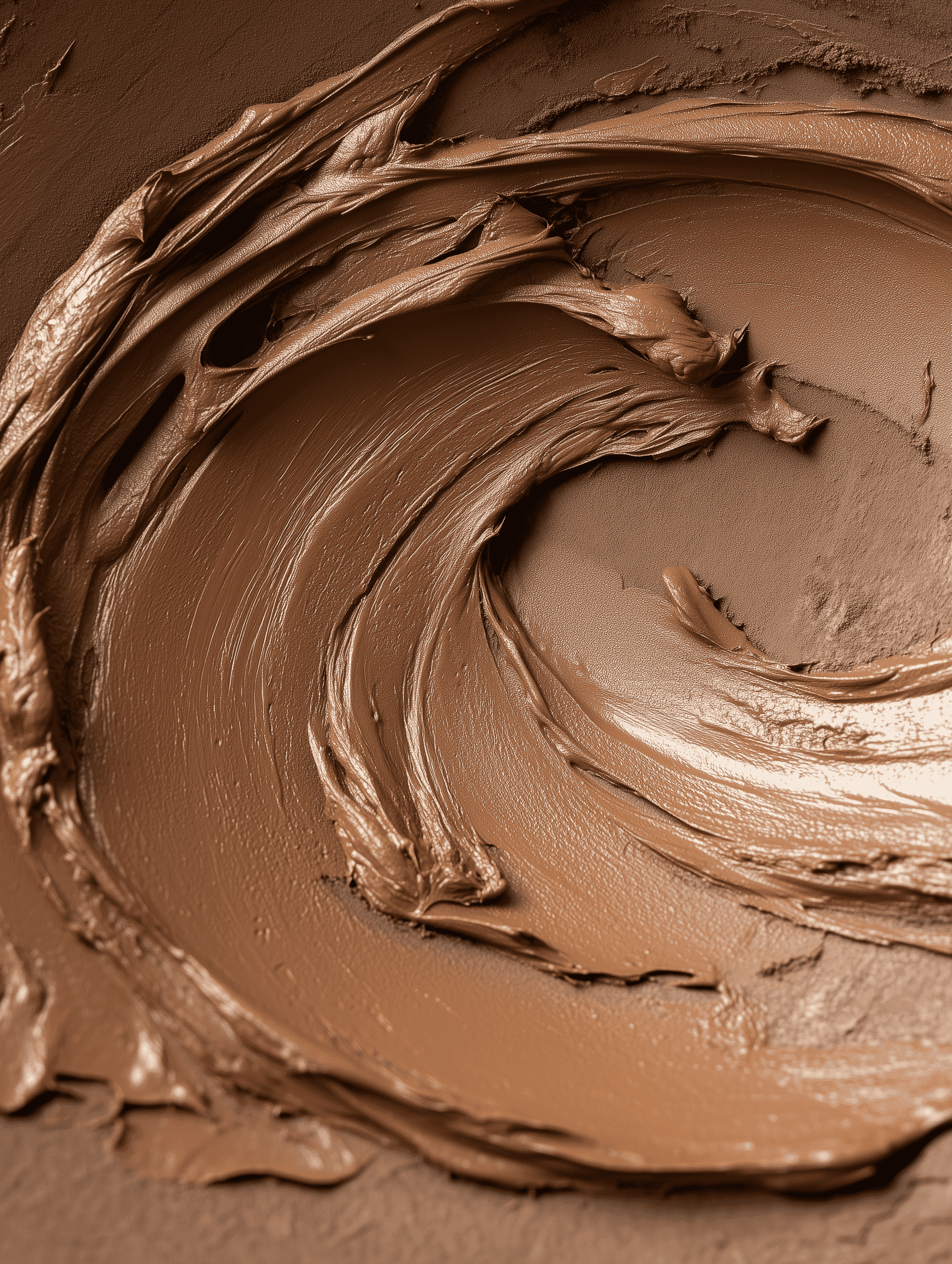

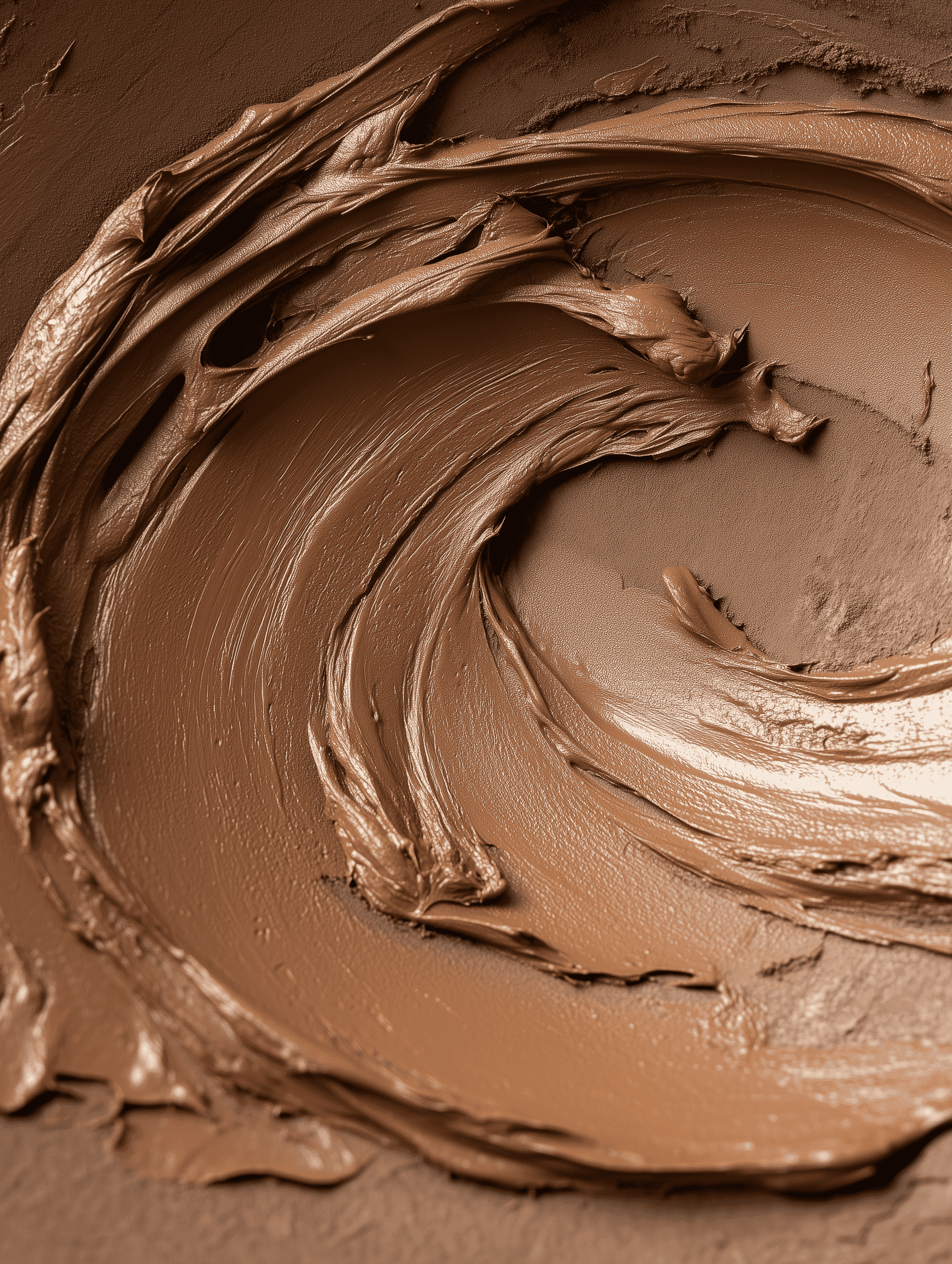

Preparation of the material and paste

The manufacturing process begins with the selection of raw materials, where different types of clay are mixed with water to form a homogeneous paste. The paste is then transformed into slabs of clay, which are cut and molded to the desired size and shape. Through an efficient process, we are able to create a wide variety of excellent flower pots and planters, ready for production.

Piece Formation

Once prepared, the paste is cut into specific portions and molded in presses that guarantee the final shape of each piece. This process ensures that each flower pot or planter has the desired shape and finish, ready for the next stages of development. In addition, the automatic production of flower pots uses metal molds, allowing for greater precision and efficiency in their manufacture.

Thermal Treatment

Heat treatment is a fundamental stage in the manufacture of ceramic products, guaranteeing the final properties of the units. The process begins with drying the pieces in air kilns, where residual moisture is carefully eliminated, preventing deformations or defects. After cooking, the pieces are carefully checked and adjusted, guaranteeing a final product with an impeccable appearance, ensuring its readiness for painting or other customizations.

Painting

In the painting department, objects gain color and identity. Using modern techniques such as electrostatic painting, each item is transformed into a unique piece, with high-quality finishes that meet decorating trends and the preferences of each client.

Logistics

Finally, the pieces are carefully prepared for transportation. Each piece is packed safely and efficiently, ensuring that it arrives at its destination in perfect condition. This meticulous work is essential to preserve the caliber and care taken throughout the production process when picking them up.

Departments

Preparation of the material and paste

|

Piece Formation

|

Thermal Treatment

|

Painting

|

Logistics

The manufacturing process of each ceramic piece is meticulously organized, involving six specialized departments that ensure maximum efficiency and compliance with first-rate standards of excellence.

Preparation of the material and paste

The manufacturing process begins with the selection of raw materials, where different types of clay are mixed with water to form a homogeneous paste.

The paste is then transformed into slabs of clay, which are cut and molded to the desired size and shape. Through an efficient process, we are able to create a wide variety of excellent flower pots and planters, ready for production.

Piece Formation

Once prepared, the paste is cut into specific portions and molded in presses that guarantee the final shape of each piece. This process ensures that each flower pot or planter has the desired shape and finish, ready for the next stages of development. In addition, the automatic production of flower pots uses metal molds, allowing for greater precision and efficiency in their manufacture.

Thermal Treatment

Heat treatment is a fundamental stage in the manufacture of ceramic products, guaranteeing the final properties of the units. The process begins with drying the pieces in air kilns, where residual moisture is carefully eliminated, preventing deformations or defects. After cooking, the pieces are carefully checked and adjusted, guaranteeing a final product with an impeccable appearance, ensuring its readiness for painting or other customizations.

Painting

In the painting department, objects gain color and identity. Using modern techniques such as electrostatic painting, each item is transformed into a unique piece, with high-quality finishes that meet decorating trends and the preferences of each client.

Logistics

Finally, the pieces are carefully prepared for transportation. Each piece is packed safely and efficiently, ensuring that it arrives at its destination in perfect condition. This meticulous work is essential to preserve the caliber and care taken throughout the production process when picking them up.

Departments

Preparation of the material and paste

|

Piece Formation

|

Thermal Treatment

|

Painting

|

Logistics

The manufacturing process of each ceramic piece is meticulously organized, involving six specialized departments that ensure maximum efficiency and compliance with first-rate standards of excellence.

Preparation of the material and paste

The manufacturing process begins with the selection of raw materials, where different types of clay are mixed with water to form a homogeneous paste. The paste is then transformed into slabs of clay, which are cut and molded to the desired size and shape. Through an efficient process, we are able to create a wide variety of excellent flower pots and planters, ready for production.

Piece Formation

Once prepared, the paste is cut into specific portions and molded in presses that guarantee the final shape of each piece. This process ensures that each flower pot or planter has the desired shape and finish, ready for the next stages of development. In addition, the automatic production of flower pots uses metal molds, allowing for greater precision and efficiency in their manufacture.

Thermal Treatment

Heat treatment is a fundamental stage in the manufacture of ceramic products, guaranteeing the final properties of the units. The process begins with drying the pieces in air kilns, where residual moisture is carefully eliminated, preventing deformations or defects. After cooking, the pieces are carefully checked and adjusted, guaranteeing a final product with an impeccable appearance, ensuring its readiness for painting or other customizations.

Painting

In the painting department, objects gain color and identity. Using modern techniques such as electrostatic painting, each item is transformed into a unique piece, with high-quality finishes that meet decorating trends and the preferences of each client.

Logistics

Finally, the pieces are carefully prepared for transportation. Each piece is packed safely and efficiently, ensuring that it arrives at its destination in perfect condition. This meticulous work is essential to preserve the caliber and care taken throughout the production process when picking them up.